Selection of high-speed roller feeder

2020-06-23(1222)Views

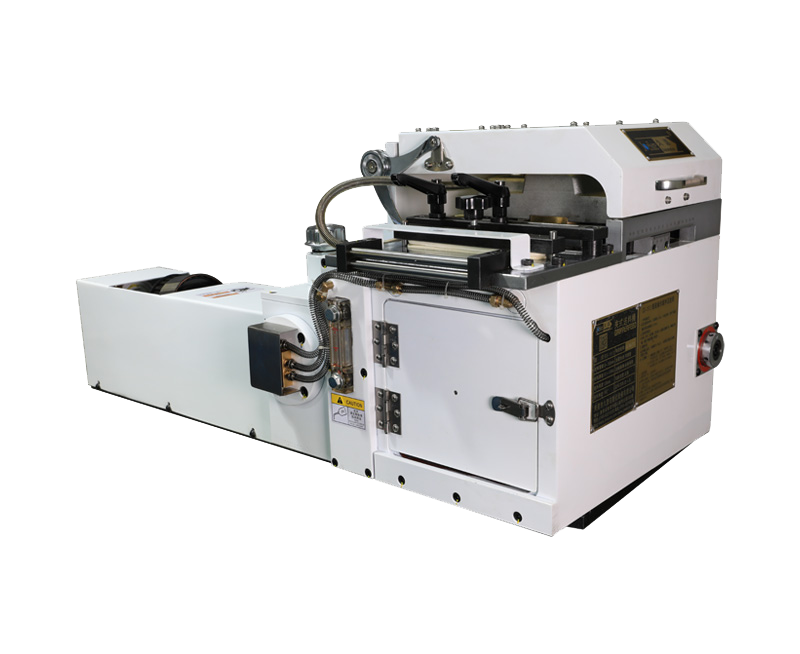

The high-speed roller feeder is the most widely used feeder in China with traditional punches, pneumatic fine punches, and high-speed punches. It has the advantages of low failure rate, no energy consumption, high degree of automation, and good stability.

The high-speed roller feeder selects the feeding method of the migraine disc, cross joint, tie rod, rocker arm, and drive shaft to drive the feed roller. It does not have power itself. The migraine disc installed on the output shaft of the punch press completes the power transmission. The structure and operation principle make the high-speed roller feeder models have many varieties and ten rare types. The feeding width, feeding step and feeding thickness of different types of high-speed roller feeder are different, and the price is also very large. difference.

Select high-speed roller feeder should pay attention to three points:

1. The punch must have an output shaft. Regardless of the type of punching machine used, the output shaft of the punching machine is a necessary device selection condition. If the punching machine does not have an output shaft, a roller feeder is also required, and the customer needs to contact the punch manufacturer to install an output shaft.

2. Clarify the maximum width, maximum material thickness and maximum feeding step of the data.

3. Clarify the punching speed requirements of the punching machine. There are two types of high-speed roller feeders: the standard model and the high-speed model. The standard model is used for the deployment of traditional punches and pneumatic fine punches. The maximum punching speed of the cooperative punch is about 200 times; the high-speed model is used for the deployment of high-speed punches. The maximum punching speed of the punching machine can reach about 600 times.

After understanding the above three points, you can choose the model according to practical needs. Also note that the type of high-speed roller feeder is composed of letters and Arabic numerals, such as RF-138NS, RF-1310NS, etc. The letters RF in the type are English abbreviations, and the 3-digit or 4-digit Arabic numerals represent the maximum feed of the machine Width and maximum feeding step, the first two digits of the number represent the maximum feeding width, the last one or two digits represent the maximum feeding step, such as 13 in RF-138NS, the maximum feeding width is 130mm, and 8 represents the maximum feeding length of 80mm. And so on.

Recommended News

-

What are the classification and advantages of the three-in-one feeder?

The three-in-one feeder is a highly efficient feeding equipm...

-

High-tension board three-in-one feeder is the future development trend

Stamping forming is an important forming method in modern ma...

-

Selection of high-speed roller feeder

The high-speed roller feeder is the most widely used feeder ...

-

Clip feeder-the preferred feeder for high-speed punches

The high-speed punching machine is the most commonly used pr...

Contact Us

Service Hotline+86 13580817073

—— WeChat communication

+86 13580817073

+86 13580817073